Foundation Pit Safety Monitoring System of Guangzhou Zengcheng District People's Hospital Reconstruction and Extension Project

The project is located at No. 1, Guangming East Road, Zengcheng District, Guangzhou City, Guangdong Province, with a construction area of 138,374 square meters, a total building height of 93.5 meters, 5 underground floors and 22 above-ground floors. The total cost of the project is about 997 million yuan. The perimeter of the project foundation pit is about 487 meters, the excavation area is about 12,000 square meters, and the excavation depth is 24.8~27.4 meters. In order to grasp the safety of the foundation pit and the surrounding buildings during the foundation pit excavation process in real time, the entire foundation pit and surrounding dangerous buildings are monitored online in real time.

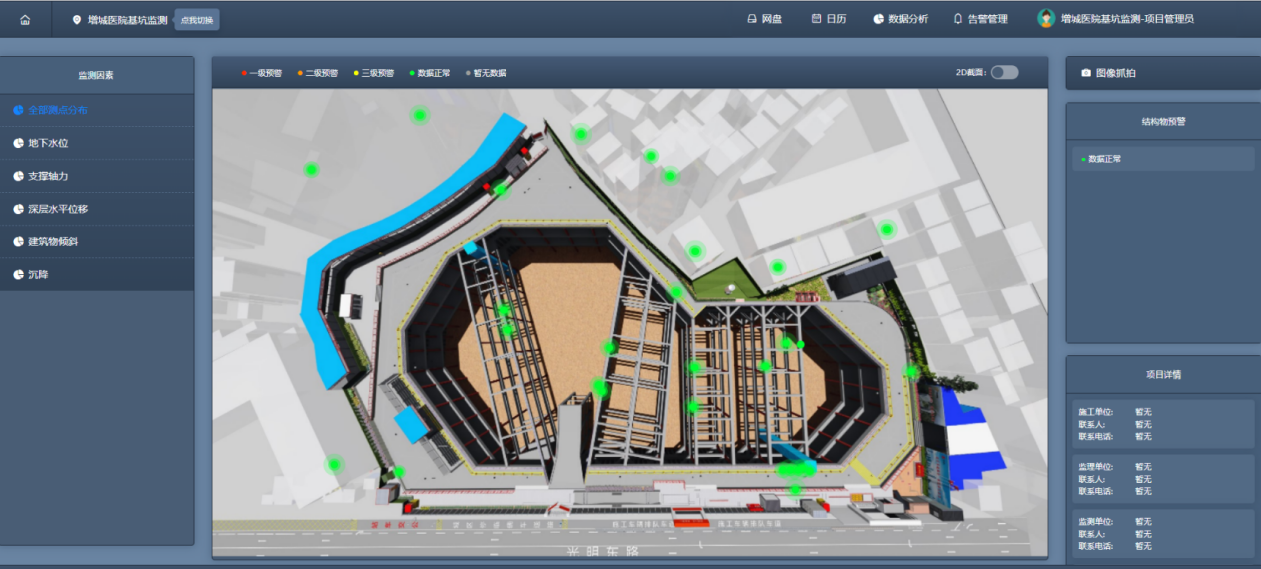

The monitoring items involved in the foundation pit safety monitoring system mainly include 12 sets of concrete support axial force monitoring systems, 5 sets of support pile deep horizontal displacement monitoring systems, 1 set of column settlement monitoring system, 6 sets of groundwater level monitoring systems and 14 sets of building tilt monitoring systems. The monitoring system uses distributed GPRS nodes for data collection and transmission, and connects the sensor monitoring data to the distributed GPRS nodes nearby, reducing the on-site wiring construction cycle and cost. The monitoring data is transmitted to the server via the 4G network. Users can view and manage the support axial force, deep horizontal displacement of support piles, groundwater level, column settlement and inclination of buildings around the foundation pit in real time through the web page and APP, providing data support for the safe construction of the project.

Construction of Guangzhou Zengcheng District People's Hospital Reconstruction and Extension Project

Support shaft force monitoring

The lateral earth pressure on the outside of the supporting system is borne by the retaining pile and the supporting system. When the actual supporting axial force is inconsistent with the axial force (design value) that the support should be able to bear in the equilibrium state, it may cause the instability of the supporting system. In order to monitor the internal force state of the support during the construction of the foundation pit, it is necessary to set the support axial force monitoring point. The support system of the supporting structure can be divided into two categories: reinforced concrete support and steel support according to the different materials of the supporting members. When monitoring the axial force of these two types of supports, appropriate test variables should be selected according to their respective stress characteristics and the structure of the components, and vibrating wire sensors corresponding to the test variables should be embedded for variable testing. Concrete support members are generally tested by steel reinforcement meters, and steel support axial force monitoring is monitored by axial force meters (also known as counter force meters) or strain gauges.

MAS-STG type steel bar gauge and MAS-EM/SM type strain gauge, the core components are made of high-quality imported steel strings, and the performance is more reliable. Built-in intelligent temperature sensor facilitates temperature correction and improves data accuracy. Strict production process, automatic production line and strict quality system create high product consistency. IP68 protection grade, standard hydraulic cable, excellent waterproof performance.

Anchor cable stress monitoring

In the stable state of the foundation pit, the side wall is subjected to active earth pressure, the enclosure structure is subjected to passive earth pressure, and there is a dynamic balance between active earth pressure and passive earth pressure. With the excavation of the foundation pit, the balance is destroyed and the foundation pit will be deformed. The enclosure structure provides active earth pressure to the soil through anchor cable tension or anchor rod. Cable dynamometers can be used to provide long-term stress change monitoring of bolts and cables. Through the stress monitoring, the stress change of the soil can be dynamically reflected in real time to ensure the stability and safety of the foundation pit.

The core components of the MAS-VHLC anchor cable meter adopt high-quality imported steel strings, which are more reliable in performance. Built-in intelligent temperature sensor facilitates temperature correction and improves data accuracy. Strict production process, automatic production line and strict quality system have created high product consistency. IP68 protection grade, standard hydraulic cable, excellent waterproof performance.

groundwater level monitoring

In foundation pit engineering, there are many factors that may induce foundation pit accidents, among which the influence of groundwater is particularly critical. Statistics show that more than 60% of foundation pit accidents are directly or indirectly related to groundwater. The change of groundwater level may cause the instability of the foundation pit slope and the excessive settlement of the surface, which will cause harm to the surrounding buildings, structures and underground pipelines. The stability and deformation problems caused by water level changes are not limited to the field of foundation pit engineering. The rise and fall of the groundwater level has serious adverse effects on the slope. Among the many factors affecting slope stability, groundwater is one of the main factors. Therefore, real-time monitoring of groundwater level plays a very important role in the safety monitoring of civil structures.

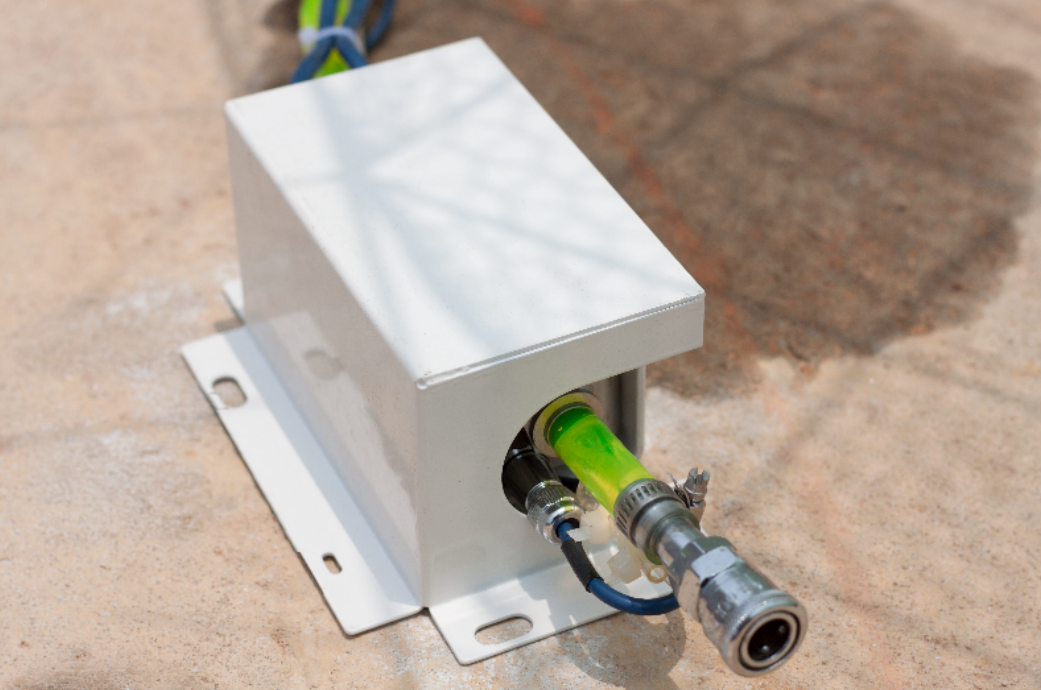

The MAS-YTSW-type intelligent integrated water level gauge is mainly composed of a pressure-type water level sensor and an acquisition and transmission module. It adheres to the design concept of high integration and low power consumption. The equipment is simple in structure, convenient to install, no external power supply, and no additional acquisition and transmission equipment. Its internal integration of 18000mAH high-capacity battery and acquisition and transmission system can work for up to 2 years, which can meet the long-term monitoring and use of customers. Product performance is stable, reliable quality, and no wiring, installation is fast and labor-saving. The integrated water level gauge data is uploaded to the cloud platform through 4G, and the water level change can be grasped online in real time through the web page or APP.

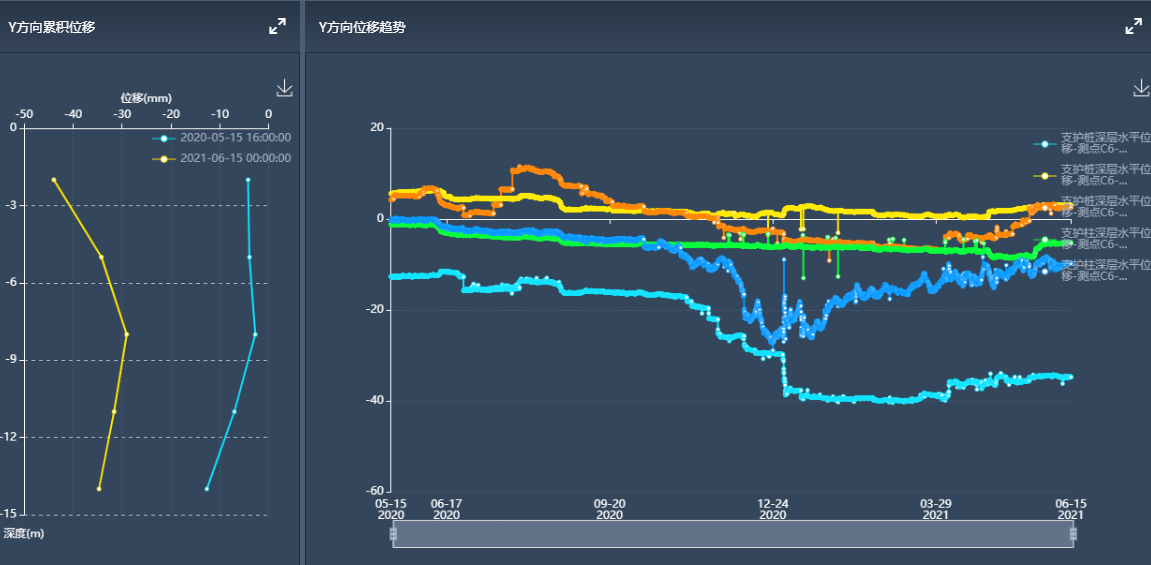

Monitoring of deep horizontal displacement of supporting structure

The earth excavation of the foundation pit, the original stress condition of the soil body changes, the outer layer of the enclosure structure exerts active earth pressure on it, resulting in horizontal displacement of the enclosure structure or the outer layer at different depths, through monitoring, sorting and analysis of the horizontal displacement of different depths, to determine whether there is a weak section, to guide the construction.

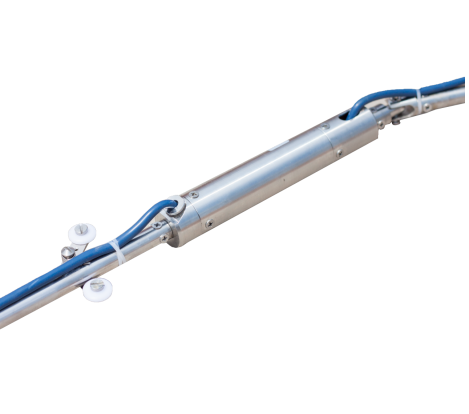

MAS-GCLI series guide wheel fixed inclinometer is mainly used for long-term automatic monitoring of horizontal displacement and inclination monitoring of dams, deep foundation pits, slopes, foundations, building bridges, ship mooring platforms, etc. The sensor adopts imported MEMES sensor, differential measurement principle, noise suppression technology, nonlinear temperature compensation and other technologies to ensure the total accuracy of the system reaches 0.01, the resolution is 0.001, the sensitivity temperature characteristic is as low as 0.013/℃, and the excellent long-term time and temperature stability of the equipment is maintained. The impact performance of the sensor is as high as 2000G, the multiple sealing design, and the shell is made of stainless steel to ensure the high reliability of the sensor. Segmented modular design, according to the application environment to increase or decrease the module, flexible application, more convenient installation.

Inclination monitoring of supporting structures/surrounding buildings

The tilt monitoring of the foundation pit supporting structure is of great significance to grasp the state of the supporting structure and ensure the safety of the foundation pit. The buildings around the foundation pit have certain risks due to the excavation of the foundation pit, so it is necessary to carry out the necessary monitoring of the buildings around the foundation pit, and the tilt monitoring is widely used because of the simple structure of the equipment and the low cost of implementation.

MAS-BCLI cassette inclinometer, range: ± 30 °, resolution: 0.0025 °, accuracy: ± 0.01 °. Widely used in buildings, bridges, towers and other structures tilt monitoring. The equipment adopts imported dual-axis MEMES sensor, differential measurement principle, noise suppression technology, nonlinear temperature compensation and other technologies to ensure high precision and excellent long-term time and temperature stability of the system. The impact performance of the sensor is as high as 2000G, the multiple sealing design, and the waterproof performance is IP68, thus ensuring the high reliability of the sensor. RS485 output, small size and convenient installation.

settlement monitoring

When deep foundation pit is excavated in soft soil area, the plastic area of soil around the foundation pit is relatively large, and the plastic flow of soil is also relatively large. The soil flows from the outside of the maintenance structure to the pit and the base, so the surface settlement occurs, which is the main reason for the settlement. The construction of underground continuous wall in the early stage of foundation pit excavation will also cause ground displacement and surface settlement. At the same time, the excavation process may also cause deformation and settlement of adjacent roads, pipelines, surrounding buildings and other facilities.

The MAS-HLS static level is mainly used for long-term monitoring of the settlement of bridges, tunnels, reservoirs, dams, buildings and other structures. Sensor range: 1000 mmH2O, comprehensive accuracy ± 0.15%FS. The sensor adopts metal film silicon pressure sensitive element, Wheatstone measuring bridge and integrated temperature sensor, and adopts intelligent temperature compensation algorithm and correction algorithm to ensure the accuracy of the equipment. The leveling system interface adopts quick connection and locking pneumatic interface, which is convenient to install, has good sealing performance and saves time and effort. Integrated manual exhaust device, air bubbles more convenient, compact appearance, stainless steel shell.

Installation of monitoring equipment for axial force of concrete support (reinforcement meter)

Installation of underground water level monitoring equipment (integrated water level gauge)

Installation of deep horizontal displacement monitoring equipment (guide wheel type fixed inclinometer)

Installation of settlement monitoring equipment (static level)

Installation of tilt monitoring equipment for surrounding buildings (box-type fixed inclinometer and integrated inclinometer)

Installation of acquisition and transmission equipment (distributed GPRS node)

Monitoring system main interface (client)

Support shaft force monitoring data

Groundwater level monitoring data

Monitoring data of deep water level displacement

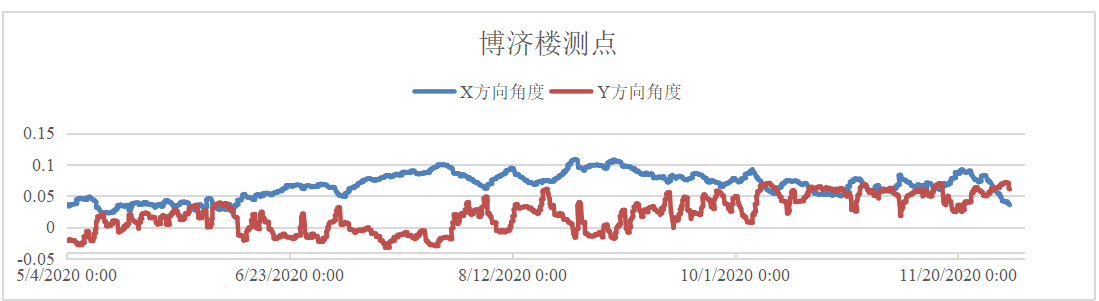

Building Inclination Monitoring Data

Previous Page