Monitoring System of MAS-GZM High Foram Support

The MAS-GZM high-support mode wireless monitoring system includes host, node, displacement sensor, weighing sensor and sound and light alarm. The system adopts wireless transmission mode, which can monitor the vertical rod inclination, template settlement, horizontal displacement and axial force of the support, and carry out pre-alarm and alarm through the all-in-one machine and sound and light alarm. Users can view the real-time data of the sensor, the power of the node and the all-in-one machine, the pre-alarm status, etc. on the all-in-one machine. The system is easy to collect, use and install, and is widely used in the monitoring of the high formwork status of various buildings under construction.

Overview

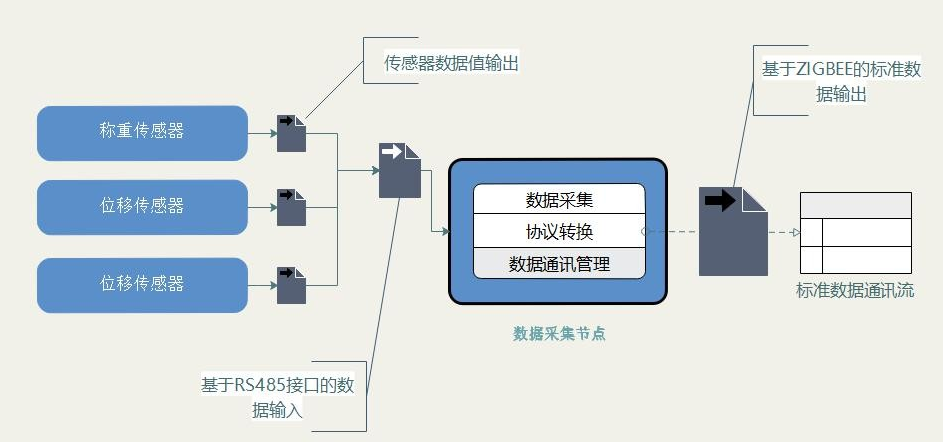

The MAS-GZM high support mode monitoring system includes an all-in-one machine, nodes and sensors, and the sensor data collected by the nodes is transmitted to the all-in-one machine through ZigBee wireless transmission. The inclinometer chip is embedded in the node, and the crack meter or weighing sensor can be connected to the outside, and the data can be output after power-on. The all-in-one machine can set pre-alarm and alarm thresholds. After judging that the data exceeds the limit, the node and the all-in-one machine can carry out sound and light alarm. Customers can upload the data to the server immediately if necessary.

Fig. 2-1 Schematic diagram of high formwork data acquisition node

Characteristics:

- Data wireless transmission, reduce wiring and the impact on the construction site;

- Multi-channel ZigBee parallel communication, efficient transmission to ensure real-time data;

- The node is powered on and outputs data, which is simple to operate;

- Node lithium battery life is long, to ensure the normal work during pouring;

- The node has IP66 waterproof performance.

Specifications

|

▼ All-in-one Machine Parameters |

|

|

Operating Temperature Range |

-10 ℃ ~ 55 ℃ |

|

Storage Temperature Range |

-20 ℃ ~ 70 ℃ |

|

Charging Power Supply |

DC24V/2A |

|

Endurance |

4.5h @ 25 ℃(16 nodes communication, data interval 5S) |

|

Maximum Number of Supported Nodes |

32 |

|

Weight |

2.5Kg |

|

Dimensions |

403mm (length) * 330mm (width) * 175mm (height) |

|

▼ Node Parameters |

|

|

Monitoring Factors |

Vertical rod axial force, vertical rod tilt, template settlement, horizontal displacement of support |

|

Range |

Monitoring of axial force of vertical rod: 0 ~ 150kN; monitoring of horizontal displacement of support and settlement of formwork: measuring range |

|

Accuracy |

Monitoring of axial force of vertical rod: 0.5 F.S; Monitoring of horizontal displacement of support and settlement of formwork: measuring range |

|

Data Transfer |

ZigBee Wireless |

|

Operating Temperature Range |

-10 ℃ ~ 55 ℃ |

|

Storage Temperature Range |

-20 ℃ ~ 70 ℃ |

|

Charging Power Supply |

DC24V/2A |

|

Endurance |

34h @ 25 ℃ (data interval 5S) |

|

Waterproof |

IP66 |

|

Weight |

0.8Kg |

|

Dimensions |

100mm (length) * 100mm (width) * 60mm (height) |

|

▼ Sound and Light Alarm Parameters |

|

|

Rated Voltage |

DC12V |

|

Protection Level |

IP65 |

|

Explosion-proof Sign |

ExDIICT6 |

|

With Light Source |

LED |

|

Sound Intensity |

110 decibels |

|

▼ All-in-one Machine Parameters |

|

|

Operating Temperature Range |

-10 ℃ ~ 55 ℃ |

Related Information

Related Product

Request for Quote